Technical R & D

Risheng Socks offers one-stop socks manufacturing service for clients

who need to make customizsed designs with our professional developing

team, even with small quantities.

Risheng Socks offers one-stop socks manufacturing service for clients

who need to make customizsed designs with our professional developing

team, even with small quantities.

Factory Introduction

Risheng Socks is a high-tech factory, who has some patents. Risheng Socks has the complete production line including many processes, which requires us to have the machines, for knitting (both single cylinder and double cylinder), toe-linking, ironing, anti-slip, printing, washing, drying, heat-transfer, etc. Each step of production must be coordinated to guarantee the quality requirements and schedule. Risheng Socks will share the production process with the customers and do our best to make each piece of socks perfact. In the meantime, Risheng Socks have some patents. We always pursue product details and meticulous service.

100+ International Brands Trusted

Cumulatively design and produce 1000000000+ pairs

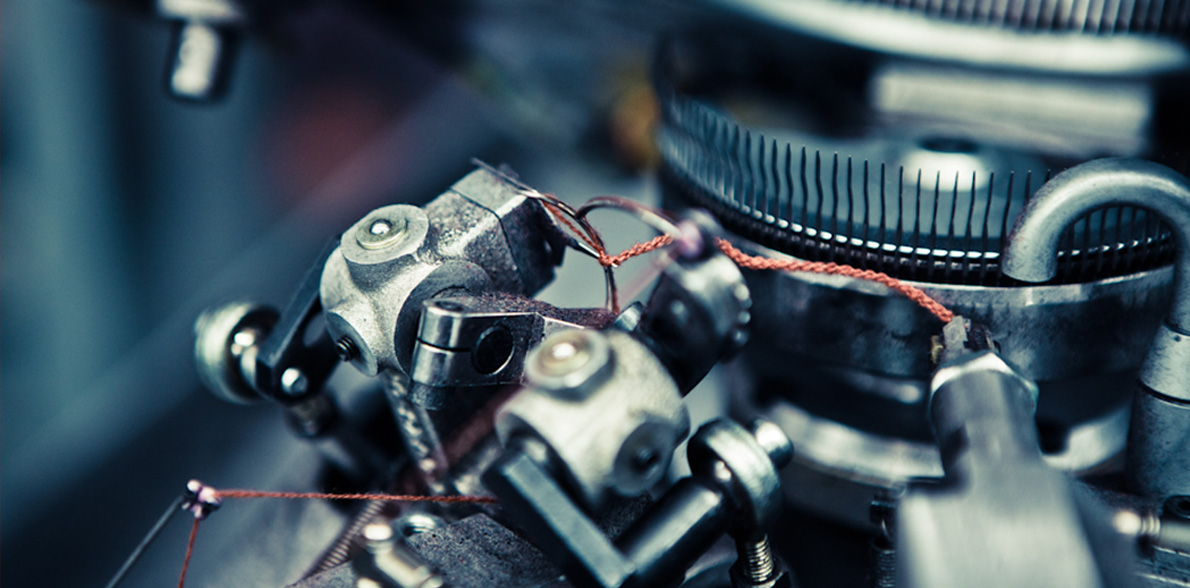

production process

Socks Designing

We have a professional design and development team, who can help customer to develop socks, even the customer are not familiar with socks.

Raw Material Preparation

After the order is placed, we will order the raw material based on the approved designs and samples.

Knitting

After the raw materials arrive, if all the raw materials are correct, the production will start as per the production schedule. The first process is knitting.

Toe-Linking

The second process is toe-linking and machine/rosso or seamless will be used as per customer requires.

Ironing

The third process is ironing if there is no additional requirement. The temperate and pressure will be adjusted and after 24 hours relaxing, the final inspection will be done.

Other Process

If additional process, like embroidery, washing, anti-slip, are required, it will be done accordingly.

Necessary Process

The production process must be based on the properties of the raw materials, the performance of machine and the requirements of the finished products. Reasonable process can shorten the production leadtime and achieve high quality, high capactity and low cost.

01. Raw Material

02. Knitting&Inspection

03. Toe linking&Inspection

04. Shaping&Ironing

05. Final Quality Control

06. Packaging

07. Metal Detect&Packing

08. Delivery

Additional Process

Clean threads

Embroidery

Cutting

Stitching/Sewing

Anti-slip print

Printing

Washing

Drying

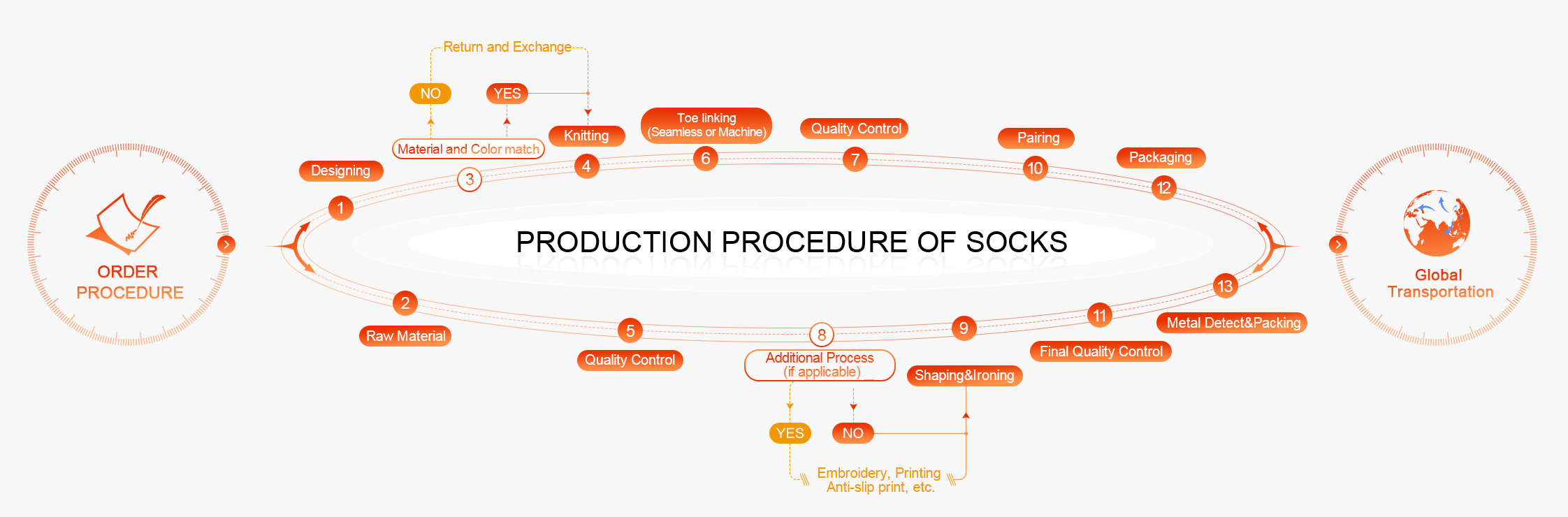

Quality Inspection

100% overall inspection, each piece of socks has been rigorously checked through four processes of knitting, toe-linking, ironing and final quality control, so that 100% inspection will be done before the socks leaving the factory.

The same batch of same color yarns provided by qualified suppliers is managed by dyeing cylinder number. After arrival, the colors are checked according to the color book. When the yarns are distributed to the workers, the same color with the same dyeing cylinder number should be used. The yarns of different cylinder numbers must not be mixed.

The worker is responsible for inspecting the socks, including checking the stretching sizes and the quality of the socks. If there is oil, it needs to be transferred out to do treatment.

Check for missing needles and poor knitting. If the pattern of the socks is complicated, the threads cut automatically by the knitting machines are too long, a specially cleaning machine will be used to ensure the threads are short enough.

After the sock has been ironed, it must be placed for 24 hours before the final quality control or other additional process can be performed in order to avoid the size shrinkage.

Checking the colors, size and quality of the socks. For example, the socks have anti-slip, embroidery, heat transfer, etc. it is necessary to check whether all the details of the workmanship are consistent with the approved samples and ensure there is no missing inspection. Then make the socks into pairs.

The packaging accessories will be distributed to the workers strictly based on the approved sample to do the packaging.

After the packaging is completed, the socks should go through a professional needle detector to detect the absence of metal substances in the socks, and then pack them into cartons after the detection is good.

Check the shipping marks on the outercarton, such as the item number, color, quantity, carton number, etc., whether they match the socks in the carton. Then the delivery will be arranged.

Yarns

Provided by qualified suppliers. Make sure the same batch of same color yarns are the same. When the material is distributed to the workers, the same color with the same dyeing cylinder number should be used. The yarns of different dyeing cylinder numbers must not be mixed.

Knitting

Strictly follow the size specification, to adjust the machine and after the samples are fully committed with the seal samples, the production will start. The knitting worker will check each piece of socks including the stretchy measurements and quality.

Toe-Linking

Machine/Rosso or seamless toe-linking will be done as per customer requires and quality control is done to ensure no missing holes.

Ironing

The ironing machine should run 3 circles in advance. As per the size specification, choosing the right temperature and pressure to do the ironing. The relaxed and stretching measurement should be within the tolerance of size specification. Relaxed placement for 24 hours in order to avoid the size shrinkage.

Final Quality Control

Checking the colors, size and quality of the socks. For example, the socks have anti-slip, embroidery, heat transfer, etc. it is necessary to check whether all the details of the workmanship are consistent with the approved samples and ensure there is no missing inspection. Then make the socks into pairs.

Packaging

The packaging accessories will be distributed to the workers strictly based on the approved sample to do the packaging. Randomly checking will be carried by the foreman.

Metal Detection and Delivery

After the packaging is completed, the socks should go through a professional needle detector to detect the absence of metal substances in the socks, and then pack them into cartons after the detection is good, then arrange the delivery.

service call:

service call: commerce@rishengsocks.com

commerce@rishengsocks.com 0086 10 8931 9688 ext 8866 or 8818

0086 10 8931 9688 ext 8866 or 8818